Production introduction

The valve adopts a three-stage combined structure, which is the arc flange, the middle flange and the valve body. When installing this product, the arc flange is removed and welded to the bottom of the tank first, and the valve body is connected with bolts;

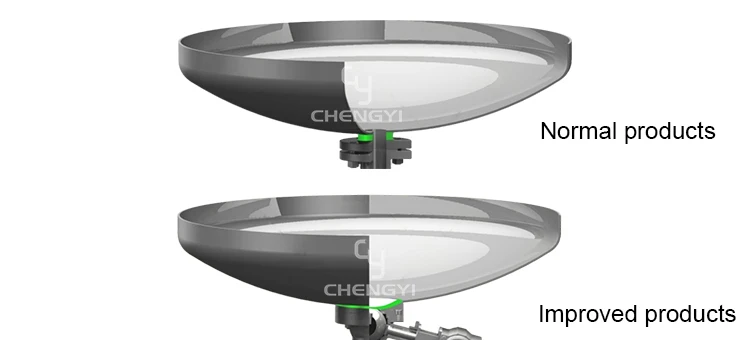

The inclined stem design avoids actuator structure have effects on the reactors; The ball adopts a no residual design, with its curved surface matching the arc-shaped flange at the tank bottom to create a seamless connection that prevents material residue. This design is primarily suitable for applications requiring bottom discharge and media with no residual substances.

The inclined stem design avoids actuator structure have effects on the reactors; The ball adopts a no residual design, with its curved surface matching the arc-shaped flange at the tank bottom to create a seamless connection that prevents material residue. This design is primarily suitable for applications requiring bottom discharge and media with no residual substances.

Product characteristic

Compact structure: compared with the usual ball valve of the same specification, the bottom ball valve is more compact, lighter weight and easier to install.

Good sealing performance: the sealing performance is reliable.

Valve stem anti-blowout design: the anti-blowout design is adopted between the valve stem and the valve body to avoid the accident of valve stem blowing out caused by improper operation.

Anti-static device is provided: anti-static device can be set up to effectively eliminate the static electricity generated in the medium in the valve.

Different valve seat materials can be selected: PTFE, RPTFE, NYLON, DEVLON, PEEK and other different valve seat materials can be selected.

Good sealing performance: the sealing performance is reliable.

Valve stem anti-blowout design: the anti-blowout design is adopted between the valve stem and the valve body to avoid the accident of valve stem blowing out caused by improper operation.

Anti-static device is provided: anti-static device can be set up to effectively eliminate the static electricity generated in the medium in the valve.

Different valve seat materials can be selected: PTFE, RPTFE, NYLON, DEVLON, PEEK and other different valve seat materials can be selected.

Advantages: No residual design

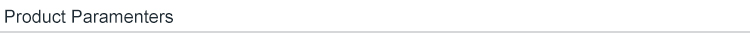

Inclined rod type DN15~DN100(1/2"~4")

Straight rod type DN125~DN200(5"~8")