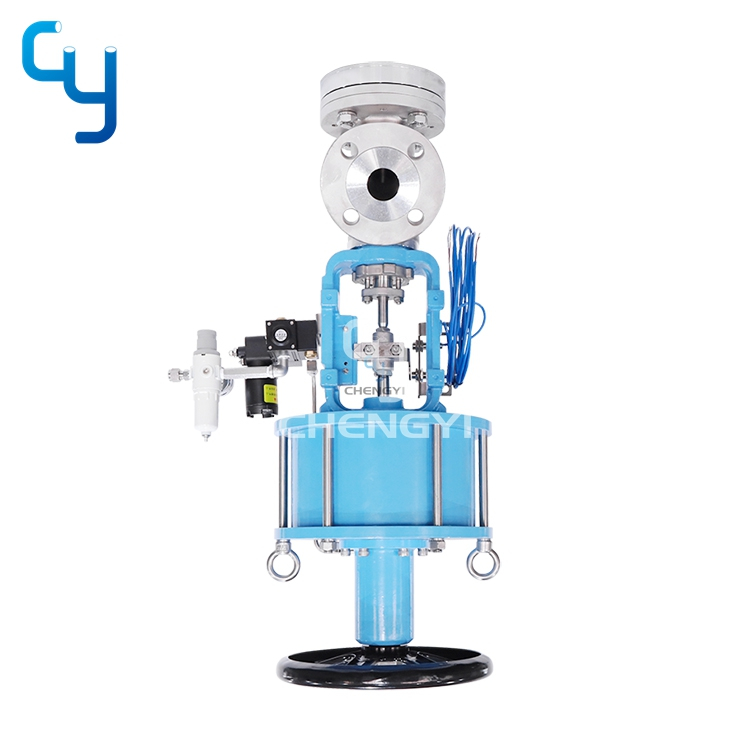

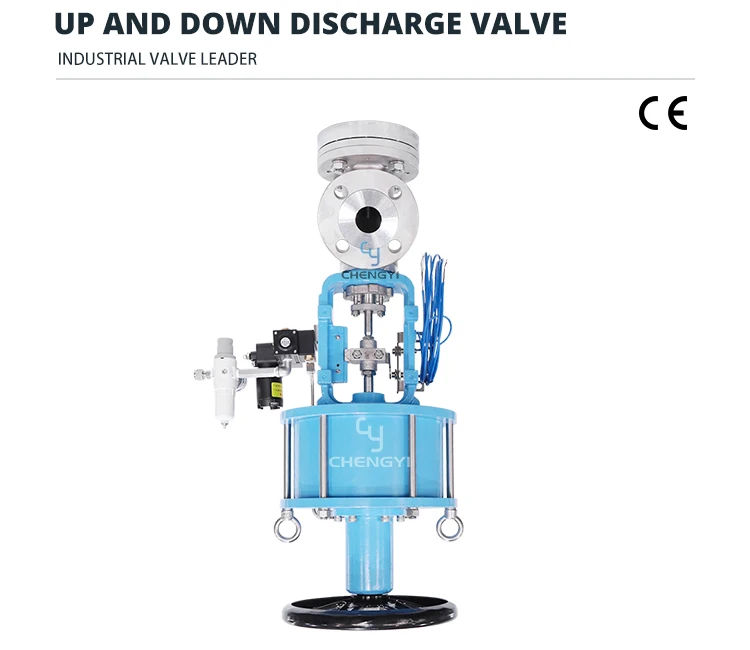

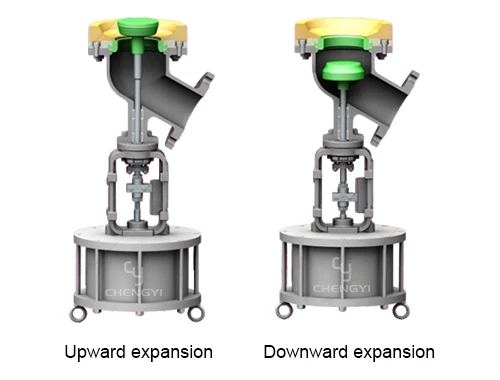

The upward type is used for reactors with agitators.

The downward type discharge valve is used for reactors with frame anchor type stirrers.

The difference between the opening and closing torque:

The upward type needs to overcome the force of the medium. When opening, the torque is larger than that of closing.

The downward type complies with the thrust of the medium. When opening, the torque is smaller than that of closing.

The upward type needs to overcome the force of the medium. When opening, the torque is larger than that of closing.

The downward type complies with the thrust of the medium. When opening, the torque is smaller than that of closing.