Mechanical mixing tank, which meets to GMP certificate requirements, is designed, manufactured and inspected in accordance with the pressure vessel standard (GB150-2011) and the steel welded atmospheric pressure vessel standard (NB/T 47003.1-2009).

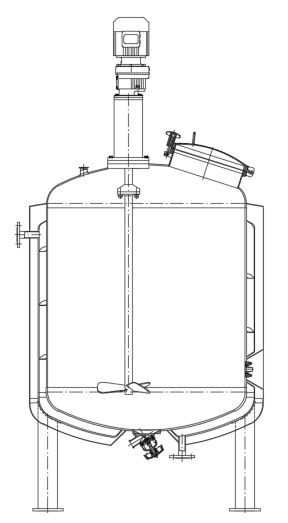

The mechanical mixing tank is a vertical tank in which the material mixing meets the requirements of process production.

Mechanical mixing tank adopts vertical circular tank. It can be with jacket and insulation. Stainless steel is made of 304 or 316L, inner surface is electropolish or mechanical polish. The outer wall adopts 304 insulation structure, outer surface is mirror polish or satin finish; The transition section of top nozzle openings and inner shell uses circular arc transition, which is without dead leg, easy to clean and beautiful appearance.

Feature

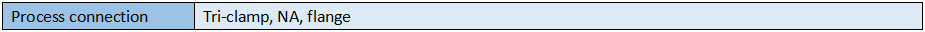

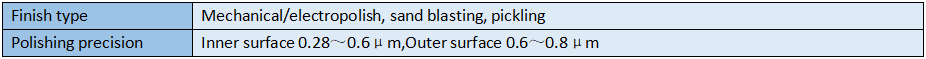

The connection adopts Tri-clamp, inner shell use 304 or 316L, inner surface is 0.28~0.6μm by mirror polish,outer surface polished by satin finish or sand blasting according to customers’requirements.

According to the requirements of production and processing, it can be designed with heating, cooling, low-high mixing system, sealing pressure system, vacuum system, measuring system and so on.

According to different mixing materials and required mixing effect, the structure of impeller can be designed in propeller impeller, turbine, anchor, frame type and so on.

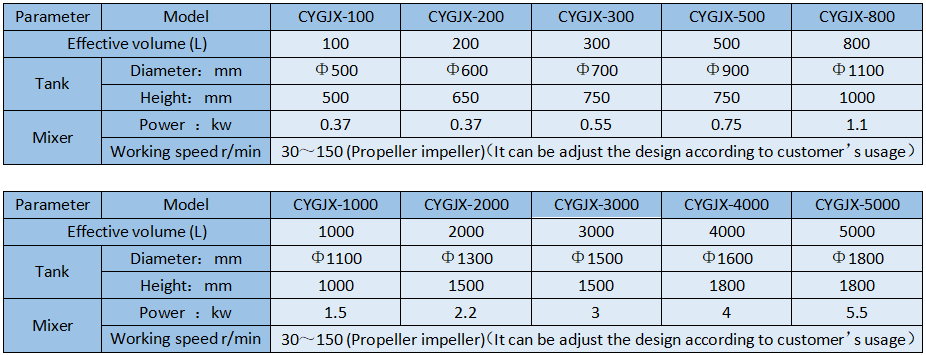

Volume range is 30L~20000L, and we can make other specification according to customer’s actual requirements.

Application

It can be used as preparation tank, mixing tank, storage tank, blending tank, etc... It suits for aseptic mixing and storage of liquid materials in medicine, food,fruit juice, beverage, dairy, seasoning, brewing, beer, pharmaceutical, chemical and bioengineering industries.

Tank optional configuration

Mechanical mixing tank can be optionally configured with sight glass with lamp, manhole, cleaning ball, vent filter, pressure gauge, sampling valve , bottom valve, thermometer (digital display or Dial type), PH probe, level gauge and level control system (load cell, static pressure transmitting device and so on). It also can be configured according to customer’s requirements.

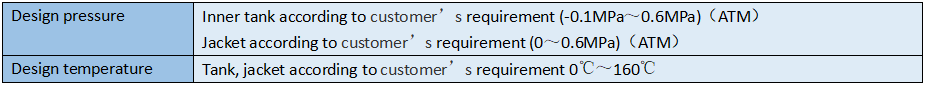

Design parameter

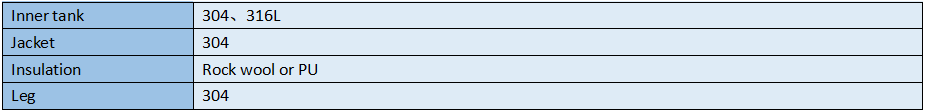

Material

Connection

Design parameter

Normal Model and Main Technical parameters

The above mentioned data is the standard, it can customize according to customer’s requirements.