Product description

Sanitary Shell & tube heat exchanger, designed for high cleanliness requirements, meets the high cleanliness requirements of the pharmaceutical industry, usually used in injection water point cooling, modular integration, process cooling or heating, etc.

Working principle

The material flows inside tube, the cold and hot medium flows inside shell, and the material and the cold and hot medium carry on the high efficiency heat exchange through the compact arrangement tube bundle to meet the technological temperature requirement. Because the heat exchanger adopts the double tube plate /Shell & Tube design, the bidirectional cross-contamination between the material and the cold and hot medium is completely eliminated.

Product performance and characteristics

Contacted material: stainless steel 316L

Internal surface finish: Ra<0.5μm

Simple structure, high heat transfer rate, easy to use

Dual-tube design to prevent leakage of service media to products

Meeting cGMP requirements

Standard design and maintenance-free

Customized upon request

Connection mode: tube side: TC Connection shell side: TC connection or internal thread

Applications

Heating of Purified water when pasteur disinfection

Cooling of terminal water points for injection water

Condensation and cooling of pure steam

Temperature control of CIP cleaning fluid

Heating and cooling of liquid material in process production

Small volume, high heat transfer efficiency.

The structure of the tube bundle is compact, the tube wall is thin, and the heat transfer coefficient is large. At the same time,the tube bundle can exchange heat evenly to the maximum extent and avoid the uneven heat transfer phenomenon of the rough tube bundle.

Sanitary TC connection, there is no unhygienic connection structure.

Simple straight pipe structure, no dead angle, no retention, can be completely emptied.

Double tube plate / shell & tube structure can completely avoid cross-contamination between tube side and shell side have higher safety.

1. Energy consumption : aseptic heat exchanger heat transfer coefficient is large, and are installed on the injection water point,

single point heat transfer, energy consumption is very low.

2. Installation: small size, light weight, TC connection, easy to disassemble and install. It can also reduce the cost of

installation and subsequent maintenance.

3. Safety production: directly installed in the clean room use point, if there is leakage, can be found immediately; in addition,

single point cooling, do not affect the WFI of the main circulation pipeline, can minimize harm, reduce production costs.

4. Cleaning: CIP, disassembly off-line cleaning is also very convenient.

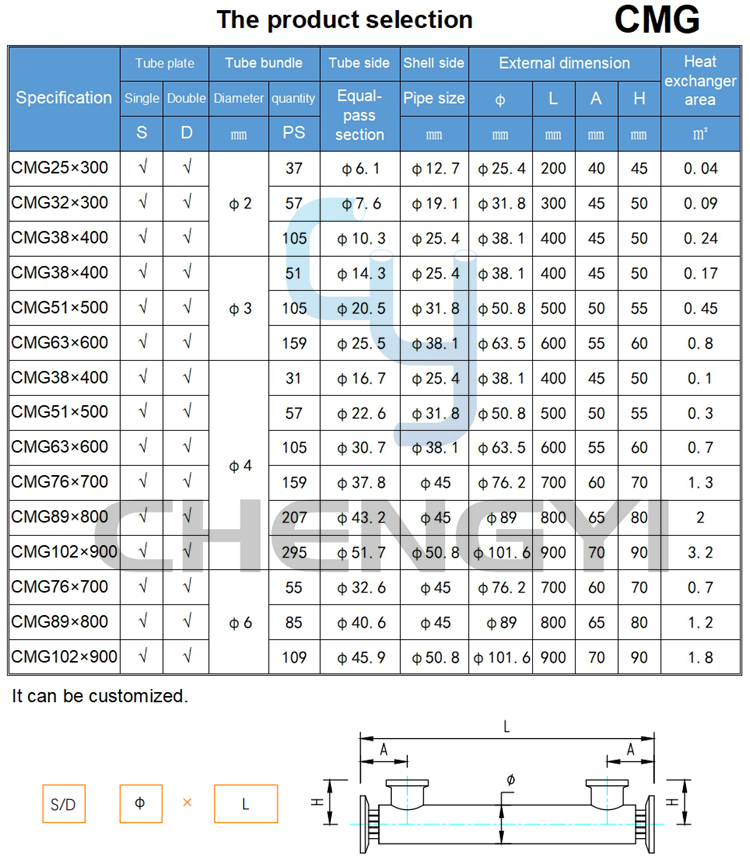

Mini Shell & Tube Heat Exchanger