Application

Pasteurization

Normal cooling and heating in dairy, brewage, beverage, food industries, etc

Heating and cooling in pharmaceutical industry

Standard design

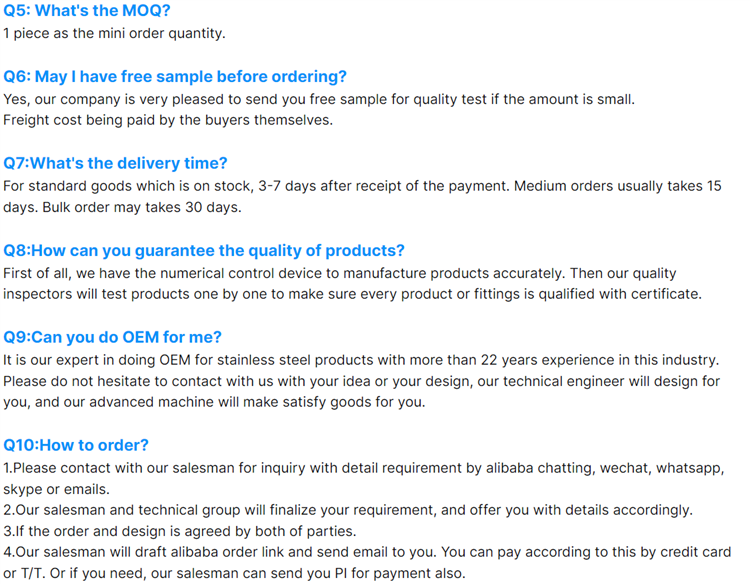

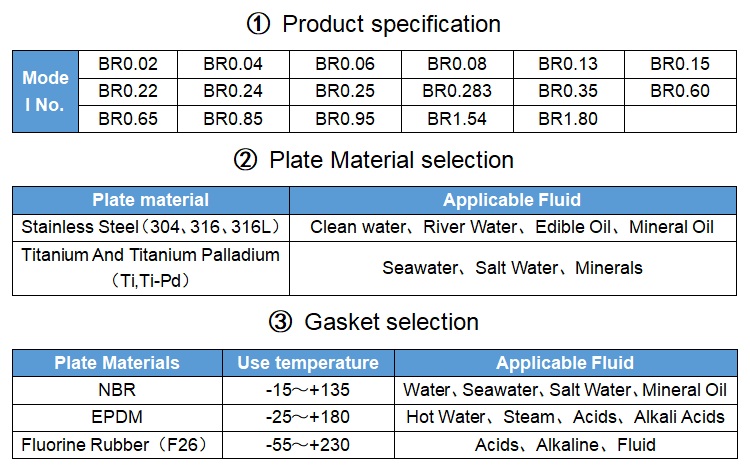

Frame

The plates and compression plates are suspended from the upper load bar and are positioned by means of the lower guide rods which are fixed through the struts and ard fitted with washers on the tensioning bolts for disassembly of the equipment, frames and columns with adjustable supports.

A device may include many heat exchangers, which are separated by connection boards with interchangeable connectors.

Front plate

The front plate is used for meeting higher requirements in food processing. The combination of the high pressure depth, plate type and relatively few contacts make the running time longer and there will have no interruption. The diversing type can ensure that the liquid flows the whole plate. The end diameter enables it to carry out CIP cleaning with the same fluid it uses during the use.

Sealing gasket

The heat exchanging plate is provided with the sealing gasket that is not bonded by glue. Users can carry out easy replacement operatio of the sealing gasket even when the plate suspends inside the frame.

Working principle

Pasteurization

Normal cooling and heating in dairy, brewage, beverage, food industries, etc

Heating and cooling in pharmaceutical industry

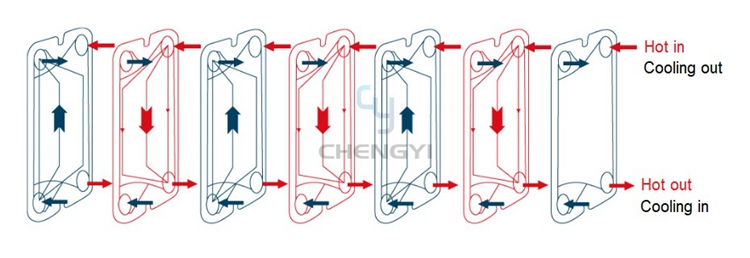

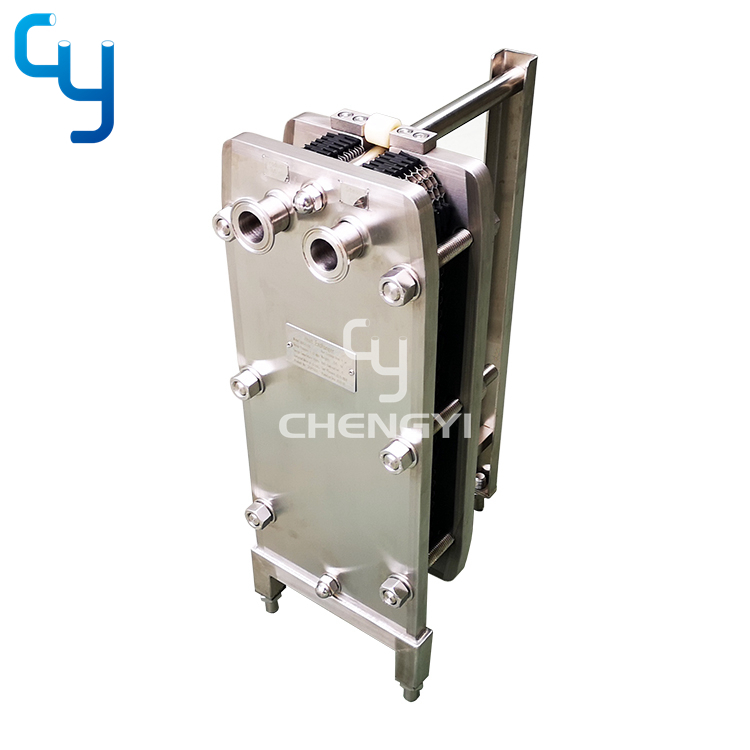

The plate heat exchanger is composed of group of corrugated metal plates. The holes on it form channel for liquids to flow, and the heat will be transferred between two kinds of liquids.

The plates are assembled between a fixed frame board and a moveable clamping board and are tightened by the tightening bolts.

These plates are installed with sealing gasekts. The sealing gaskets play the sealing function on the channels between plates and make the liquids flow into adjacent channels. The quantity of plates are determined by flow, physical properties and temperture of liquids. The joints can be located on the frame board and claming board.

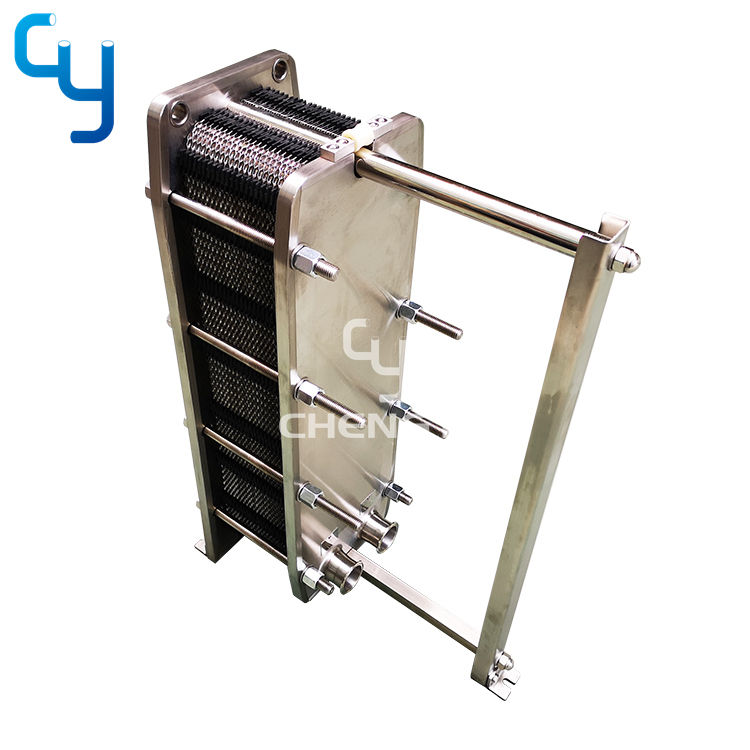

Standard materials

The frame and clamping board can be subjected to painting on the surface or coated by stainless steel. The movable nut on the fastening bolt is made of carbon steel and stainless steel.

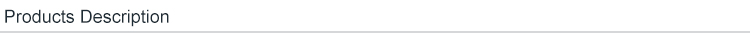

Plate type

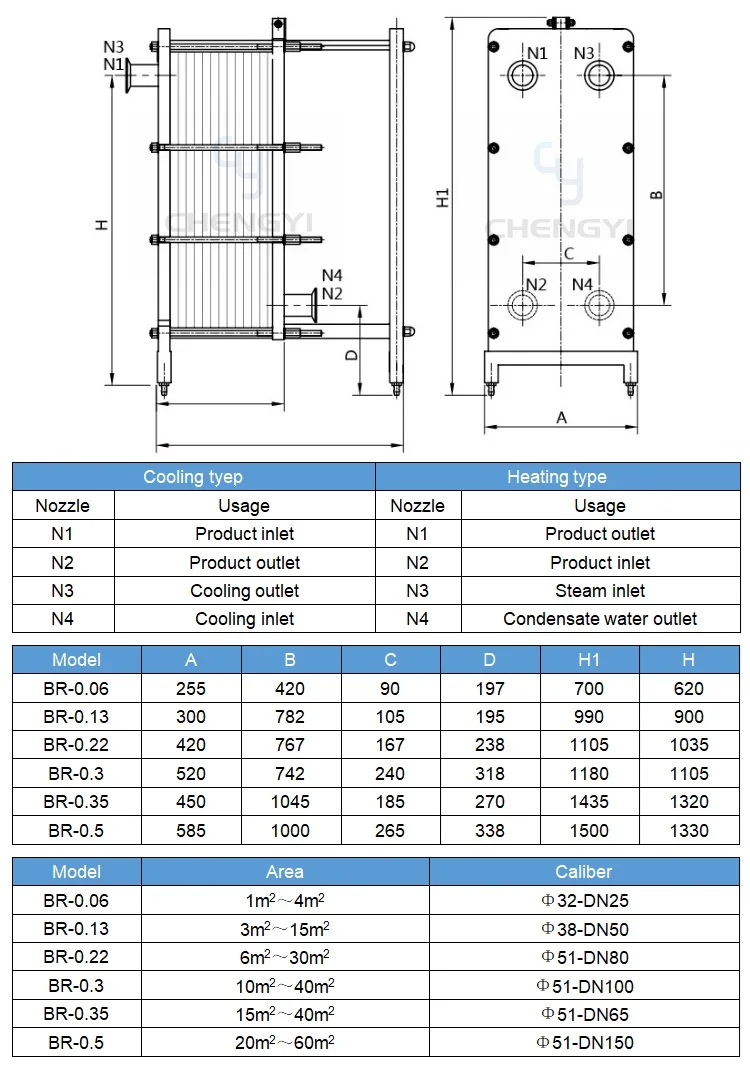

BR-0.06, 0.13, 0.22, 0.3, 0.5, 0.65 Plate: Stainless steel SS304, 316, 316L

Sealing gasket type

NBR or EPDM, Silicone Q

Technicals

Mechancial designed pressure/temperature

Designed pressure 1.0Mpa

Woring pressure 0.6Mpa

Working temperature -10 degree to 150 degree

Joint type

DIN, SMS, ISO, males thread or customized

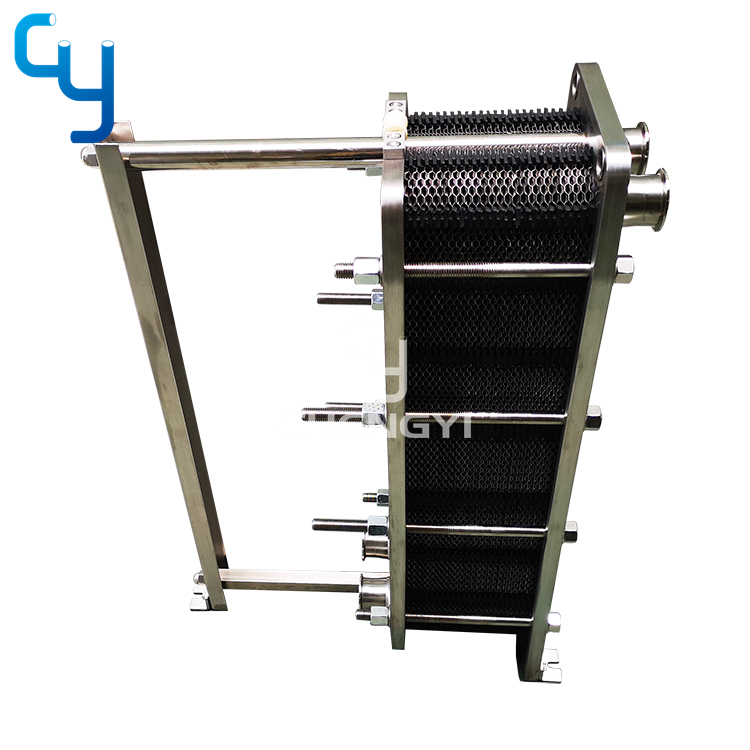

Plate heat exchanger specifications:

There are two types of plate heat exchangers: BR type and BRB type. The specifications of a variety of plate heat exchangers are as follows: Code:

B R 0.13 1.0 8 N I

No.: 1 2 3 4 5 6 7

Comments are as follows:

No. 1 represents plate heat exchanger

No. 2 representative plate type is herringbone ripple

No. 3 represents 0.13 type, also means single sheet heat exchange area is 0.13m²

No. 4 represents design pressure 1.0Mpa

No. 5 represents the entire heat exchange area of 8m²

No. 6 represents NBR rubber seal

No. 7 represents the frame shape structure is double-support frame type (also known as hanging type)

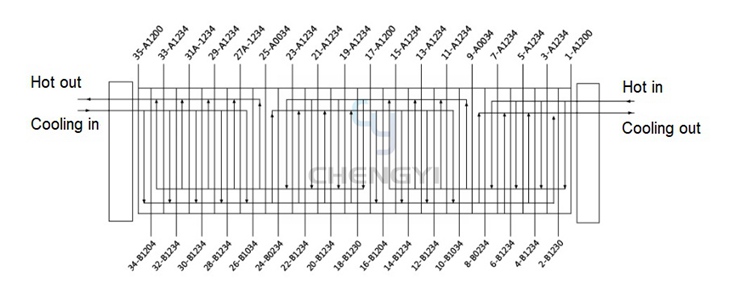

The plate heat exchanger is provided with various flow combination types, which are all realized by adopting different reversal plates and different assembling methods. The flow combination is divided into signel flow, multiple flow and mixed flow, which shall be selected according to the technological requirements. Generally, the medium with its temperture difference higher than 1.8 times the logarithmic average temparature difference should adopts the multiple flow, with an inter-plate flow rate of 0.3-0.5 M/S; if the flow rate is too low, the double flow or multiple flow should be applied.

Parallel connection flow combination figure