Application

The constant pressure adjust valve can guarantee a stable pressure at the inlet and outlet of the valve, so it is widely used in the rear of separator, heat exchanger, tank system and as overflow valve.

Work principle

The constant pressure adjust valve is operated remotely by compressed air, and the operation of the valve does not depend on any sensor in the pipeline that conveys the product, Only a pressure regulator for compressed air and a pressure gauge for monitoring the pressure on the product delivery line are required. A diaphragm / stem system can react quickly to any pressure change in the product delivered and change the stem position relative to maintain the preset pressure value. When the pressure of the delivery product increases, the valve opens. Conversely, the valve closes when the pressure of the delivery product is reduced.

Standard design

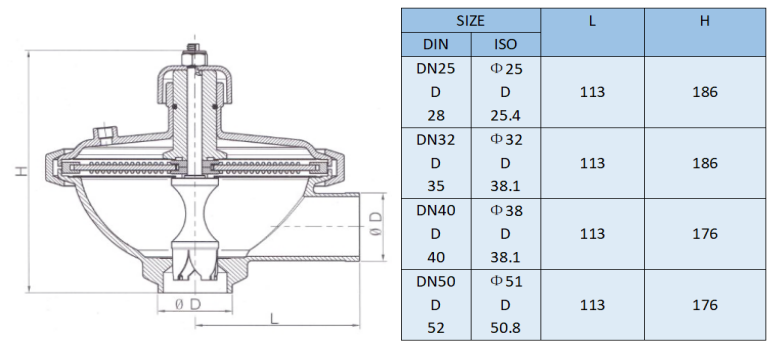

Constant pressure regulating valve series according to DIN standards, 3A standards and ISO standards to design and manufacture. Constant pressure regulating valve series basic component parts, including: a body with a valve seat, valve cover, a stem cell with a diaphragm and a clamp. Constant pressure regulating valve due to the bottom with the entrance in 90°, the residue can not accumulate, so the clean function and more significant; other special plunger design allows less liquid flow and higher CIP flow.

Technical Data

Material | Product affected with damp steel | 316L(1.4404) |

Other parts | 304(1.4301) | |

Diaphragm material | Up diaphram | NBR |

Down diaphram | PTFE/EPDM | |

Pressure | air pressure | 0kpa-800kpa (0bar~8bar) |

Flow rate | Approx 7m3/h | |

Connection | welding | |

Standards | 3A, DIN, SMS, IDF, RJT, ISO | |

Specification | 1"-2", DN25-DN50 | |

Sanitary constant pressure adjust valve