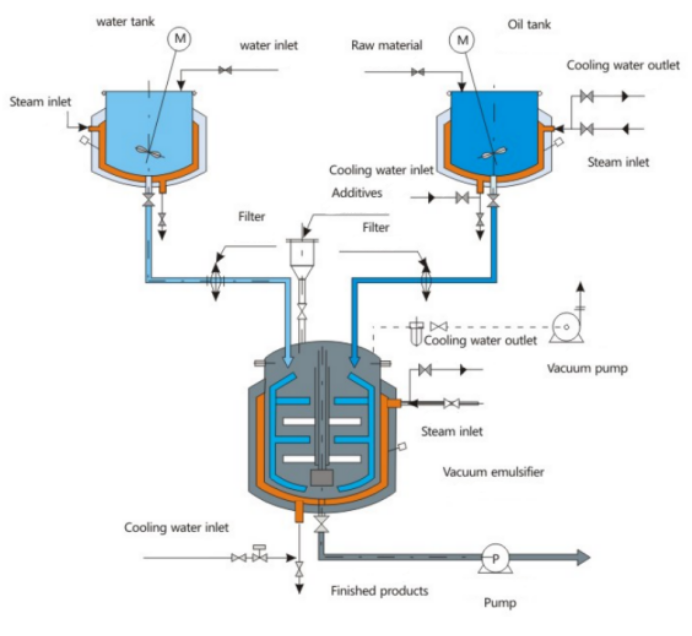

Process chart

Product description

This machine is composed of large vane mixer used for mixing materials of high viscosity materials and small strong cutting type homogenizing mixer for high speed mixing.

The scrapers are provided around vanes of mixer. The materials sticking to vessel wall can be effectively eliminated by the scrapers so as to realize sufficient blending of materials. Under the cutting, pressing and folding functions by two sets of reverse mixers, the scraped treatment fluids are mixed and will flow downwards to the position below the vessel where the homogenizing mixer can carry out pretreatment.

High-shear dispersion and emulsification is to distribute one phase or more to another continuous phase in a highly-efficient, rapid and even way. Generally, the phases are mutually indissoluble. The materials will be processed in the narrow space between stator and rotor by high tangential speed and strong energy of motion respectively produced by fast-turning rotor and high frequency mechanical effect. By the operation of intensive shearing, centrifugal extruding, liquid layer attrition, impacting and breaking, and even turbulence, the materials of mutually indissoluble solid phase, liquid phase and gas phase will be refined, dispersed and emulsified instantly with the help of mature technology and proper amount of additive. After high frequency reciprocating circulation, products of stable quality are achieved.

As shown in the above,the homogenizing mixer and vane mixer complement each other with their respective features for effectively realizing emulsification and mixing of materials of high granularity.

Product features

1. For materials of super high viscosity (above 50.000 C.P.S). We recommends the use of corresponding high viscosity emulsifying homogenizer.

2. Raw materials can be directly sucked into the groove by the machine.

3. The machine is provided with vacuum, hydraulic pressure, heating, cooling and other functions.

4. Emulsifying, blending and dispersion can be completed within a short period of time.

5. Slow speed blade type blending and high speed homogenizing systems are provided with frequency conversion control.

6. Users can select push button control or PLC touch screen system.

7. Parts that contact materials are made of stainless steel SS316l. The whole equipment conforms to GMP standard.

8. Blending is carried out under vacuum to effectively ensure the emulsifying effect.

9. The equipment is provided with the CIP cleaning device, which can conveniently use the self-contained CIP cleaning system of users to clean the equipment.

The machine has easy operation, steady capability, good homogeneity, high efficiency, reasonable structure, small volume and high automation level and easily clean.

Product advantages

The machine has triple blender, hydraulic lift cover, high-speed homogeneity blender (Speed is 0-3500r/min, frequency speed regulation) and low-speed scraper blender (Speed is 0-40 r/min, frequency speed regulation). The homogenizer adopts high shear jet type emulsifying mixer, and slowly scraping agitator automatically adheres to the bottom and wall of the vessel. The machine draws powder material by the way of vacuum in order to prevent the powder flying. The whole working procedure is operated in the condition of vacuum in order to prevent the material coming into being bubble after high-speed blending and reach the request of sanitation and asepsis. CIP cleaning system is equipped in this system. The contact parts of vessel and material is made from SS316L material. Inside is mirror polish, outside is satin finish. The machine is made according to the GMP request.

Application

Food, medicine, cosmetics, chemical raw materials.