Emulsifying tank, which meets to GMP certificate requirements, is designed, manufactured and inspected in accordance with the pressure vessel standard (GB150-2011) and the steel welded atmospheric pressure vessel standard (NB/T 47003.1-2009).

Emulsification tank is used to mix one or several materials (Water soluble solid, liquid or jelly) with a other liquid and then to hydrate it into Emulsion Liquid.

When the emulsifying tank is in operation, the emulsifying head rotates at high speed, which produces a strong suction force. The material is rotated down by the powerful suction of the emulsifying head, and then thrown to the stator, and ejected through the slot of the stator tooth. At the same time, the anti vortex baffle at the bottom of the tank can turn the rotation force into the up and down force, through this repeated action, the materials in the tank are mixed evenly, and the powder materials are prevented from accumulating on the liquid surface, and the purpose of emulsification and homogenization is finally achieved. The material production process is completed under the condition of airtight, safe and hygienic.

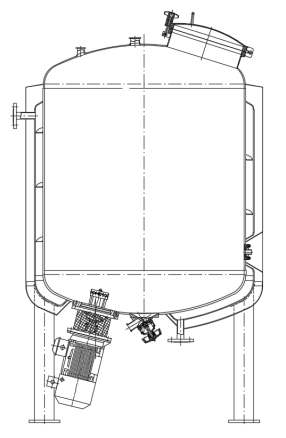

It adopts vertical circular tank. Jacket can be made in type of dimple jacket, coil jacket or full jacket, which can heat or cool. It is made by 304 or 316L.

Feature

The emulsifying tank is compact structure, small volume, light weight, easy operation, low noise and stable operation. Its biggest feature is that it has no grinding materials in production, which integrates high speed shear, mixing, dispersion and homogenization.

Reasonable diameter and height ratio design, energy saving, fast mixing of materials, high efficiency of emulsification and homogenization.

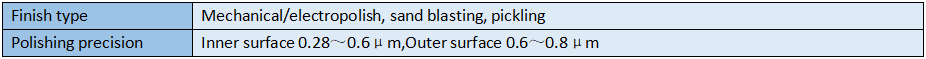

Inner surface is electropolish or mechanical polish. The outer wall adopts 304 insulation structure, outer surface is mirror polish or satin finish; The transition section of top nozzle openings and inner shell uses circular arc transition, which is without dead leg, easy to clean. It ensures the reliability and stability of the production process, and meets the requirements of GMP.

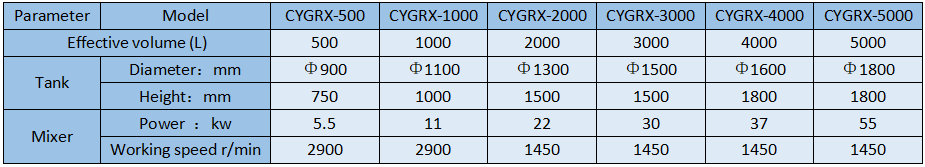

Volume range is 100L~5000L, and we can make other specification according to customer’s actual requirements.

Application

It is suitable for the manufacture of cosmetics, medicine, food, chemistry, dyeing, printing ink and other industrial products, especially for the emulsification of materials with high matrix viscosity and high solid content.

Tank optional configuration

Emulsifying tank can be optionally configured with sight glass with lamp, manhole, cleaning ball, vent filter, pressure gauge, sampling valve, bottom valve, thermometer (digital display or Dial type), PH probe, level gauge and level control system (load cell, static pressure transmitting device and so on. It also can be configured according to customer’s requirements.

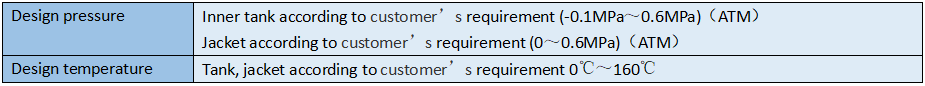

Design parameter

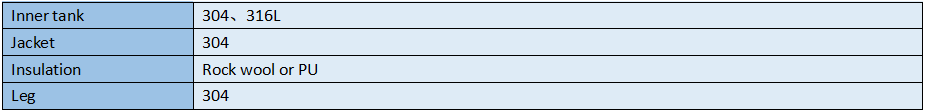

Material

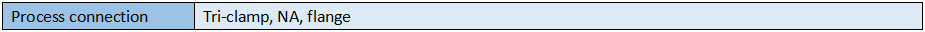

Connection

Design parameter

Normal Model and Main Technical parameters

The above mentioned data is the standard, it can customize according to customer’s requirements.