Product Introduction

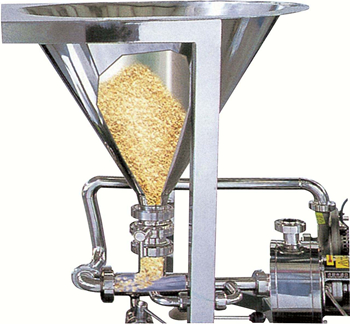

CYL-B efficient online mixer system is the latest generation of solid and liquid, liquid and the liquid fast, efficient hybrid

systems

equipment. The system has powerful central vacuum of power system to

ensure operation of the system efficient, safe and reliable, but also

the clever design of a set of precise and bite rotor will close

subsystems, making efficient online mixer with a variety of unique and

mutual reunification of the function. In the unique and compact

structure of the system, two systems synergy, working together, so that

non-homogeneous materials in a small space rapidly and thoroughly mixed

and heterogeneous, and may even be a meticulous verification of

stability to repeat production results.

System portfolio

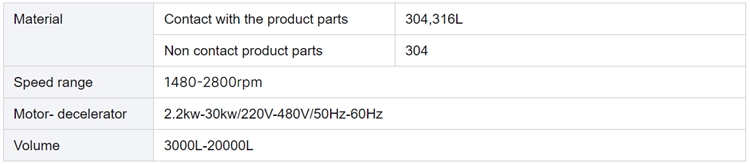

Table

system: according to different application requirements, select 304 or

316 L stainless steel manufacturing. The relatively closed system

equipment, cleaning, sanitation, safety, aesthetics, easy to operate;

Dry powder feeding: v-dry powder for solid feeding mouth with adjustable valves. Can choose manual or pneumatic control;

Control Valve:It is the necessary part of the regulating system, and can adjust the flow and velocity of the system at the same time.

System emptying system (installed according to customer requirements); can be used for cleaning, emptying and sampling.Operating system: the operating system designed, single-stop button to launch the operation, were instructed fault. Simple, easy maintenance. Operating system with anti-fertility overload, short-and anti-shortage-and to prevent misuse of the parade, such as interactive chain protection. According to customer needs, can be equipped with automatic operating system.

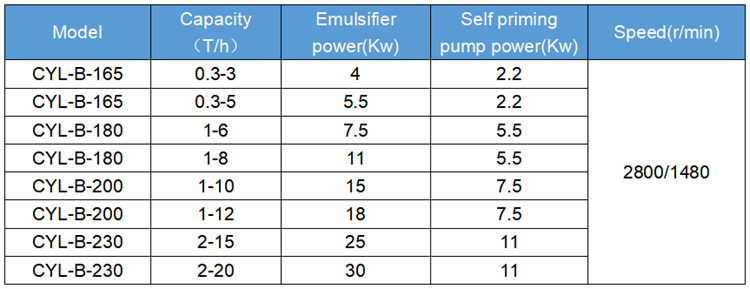

Efficient online mixer system

The above table specification is only for reference, we can customized.

1. The yield and quantity of the liquid phase were measured in water medium. Solid phase was measured in white sugar. The viscosity of liquid phase and water content of solid bulk density had great influence on yield.

2. The equipment can be customized according to the customer’s special requirements to meet the requirements of the process. Such as satisfying the viscosity, homogeneous function strengthening, heat-sensitive materials and other requirements.

3. Connection mode (clamp, thread, flange).

4. The materials of stator and rotor are stainless steel 304 ,,316L stainless steel, or high hardness steel, such as 2Cr13,9Cr18 and so on.

5. Sealing material: silicone rubber, optional fluorine rubber, ethylene propylene rubber, polytetrafluoroethylene.

6. Frequency control, non-frequency control, explosion-proof design, non-explosion-proof design.