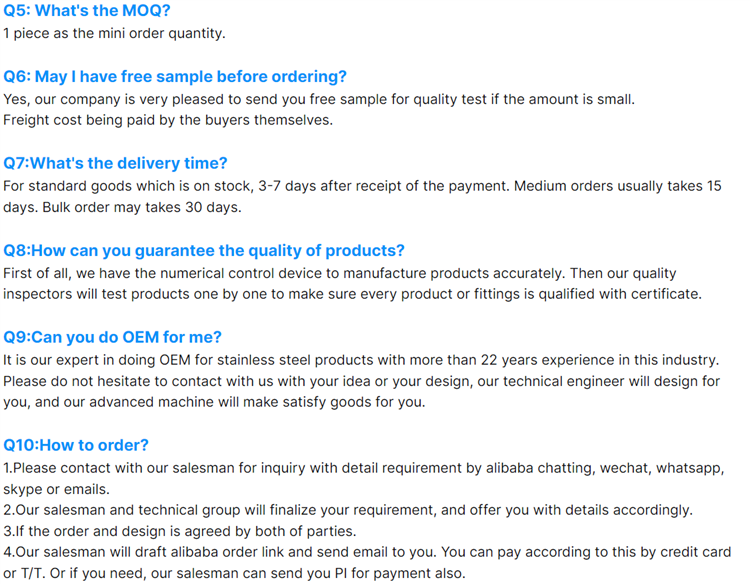

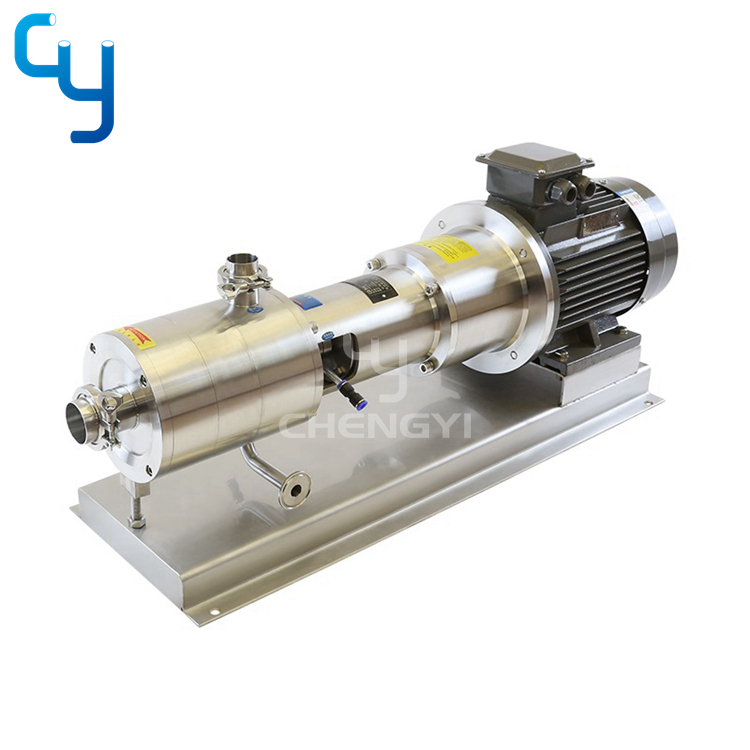

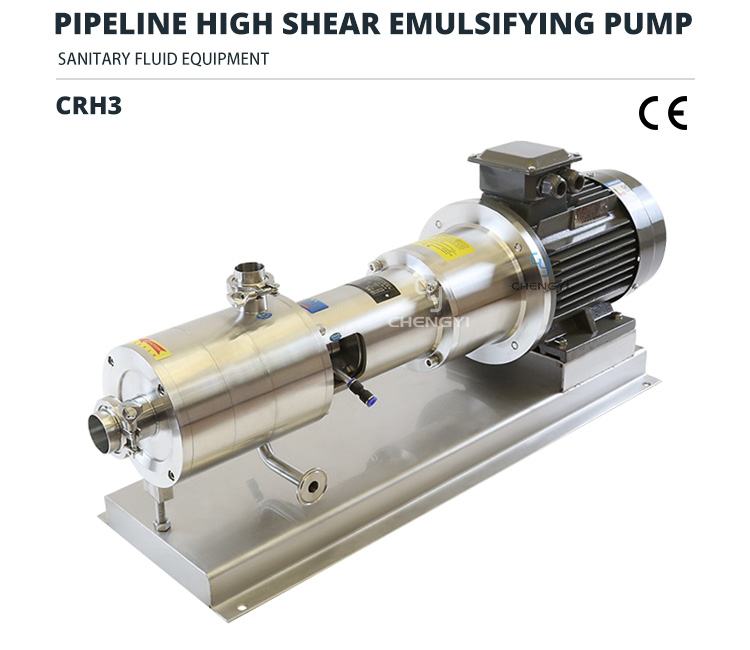

Working principle

Pipeline

high shear dispersing emulsifier is a high performance equipment used

for continuous production or circulated treatment of fine materials. In

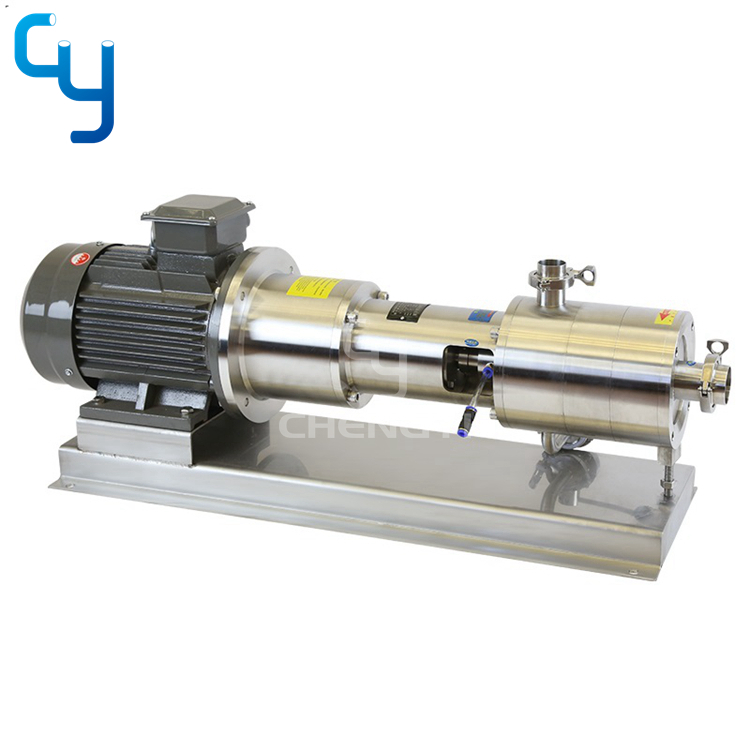

the small chamber, there are 1~3 sets of paired and clutched stators and

rotors. Driven by motor, the rotor revolve quickly and produces a

strong axial suction force which intakes the material to the chamber.

The machine disperses, shears and emulsifies the materials in shortest

time, and the diameter range of the particles gets smaller so that fine

and stable products are produced.

Three sets of stators and rotors

are equipped in working cavity. Driving shaft in working cavity is an

arm, electrical motor and the shaft in bearing cabinet can be connected

by spring coupling to improve the operation quality of driving shaft.

Seal form can be selected in different conditions. It is fit for

middle-large scale on-line continuous production or circulated treatment

production process.

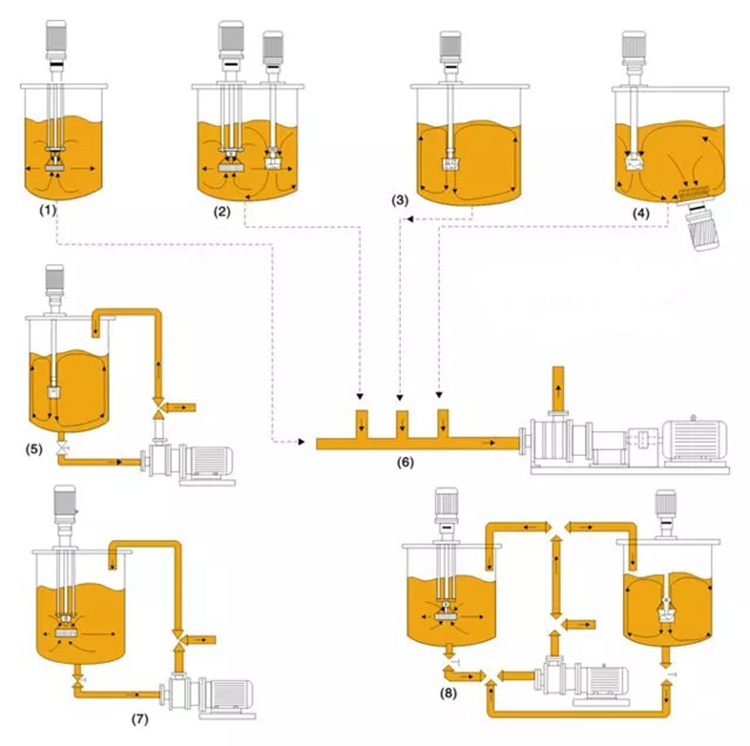

Application

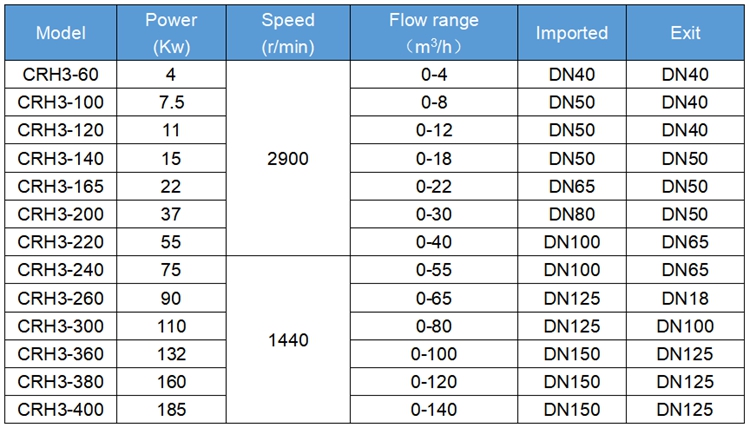

Pipeline high shear emulsifying pump

The above table specification is only for reference, we can customized.

Application

Mixing dissolving:

Soluble solid or liquid blends together with liquid in the state of the molecule or the gum

Crystallization

powder, salt, sugar, ether sulphate, abrasive, hydrolysising colloid,

CMC, thixotropy, rubber, natural and synthetic resin.

Dispersed suspension:

Unsoluble solid or liquid forms finer particle blended solution or suspended solution

Catalyst, flatting agent, pigment, graphite, paint coating, alumina, compound fertilizer, printing ink, packing agent, weed killer, bactericide.

Emulsification:

Unsoluble liquid together with liquid does not separate

Cream, ice cream, animal oil, vegetable oil, protein, silicon oil, light oil, mineral oil, paraffin wax, wax cream, rosin.

Homogeneity:

Make emulsification and suspended grain size finer with more even distribution

Cream, flavouring, fruit juice, jam, condiment, cheese, fat milk, toothpaste, typing ink, enamel paint

Thick liquid:

Cell’s tissue, organic tissue, the animal and plant tissues

Chemical reaction:

Nanometer material, inflating with higher speed, synthesization with higher speed

Extraction:

The vortex extraction

Depolymerization:

Nanometer powder, dough powder