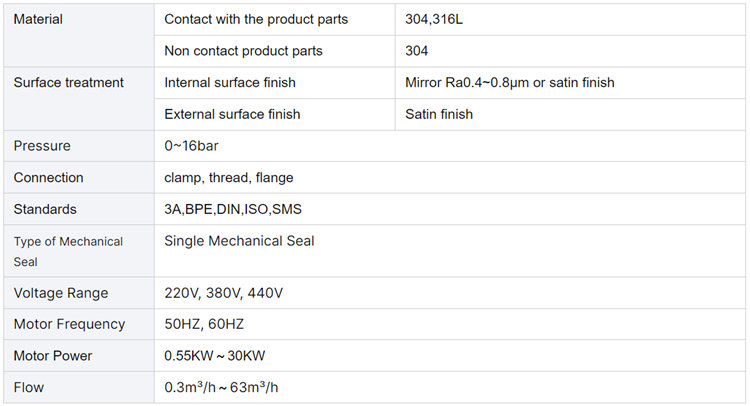

Operation principle

The

rotor pump has two synchronously reversed rotors (2-4 teeth). When they

rotate, there is suction (vacuum) generated at the inlet to suck in the

material to be transported. The two rotors divide the rotor chamber

into several small pieces. In the space, they operate in the order

a→b→c→d. When operating to position a, only chamber I is filled with

media; At location b, part of the medium is enclosed in room B; At

position c, the medium is also enclosed in chamber A; At position d,

Room B and Room A communicates with Chamber II, and the media is

conveyed to the discharge port. In this way, the medium (material) is

continuously sent out

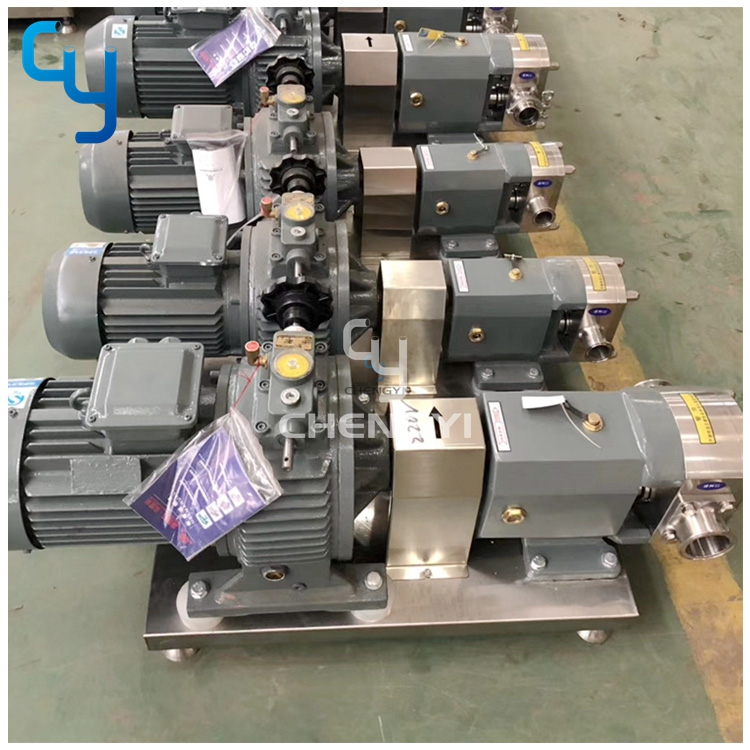

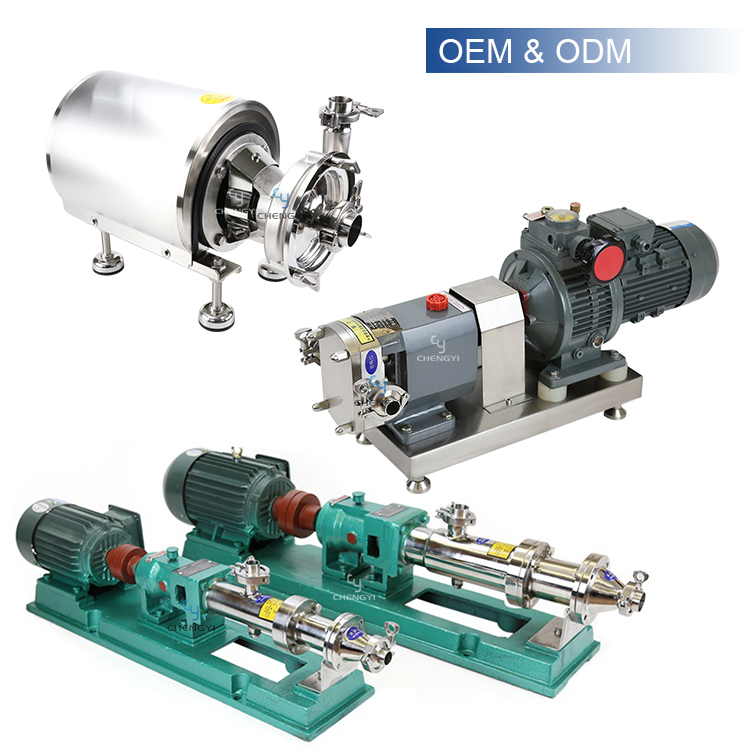

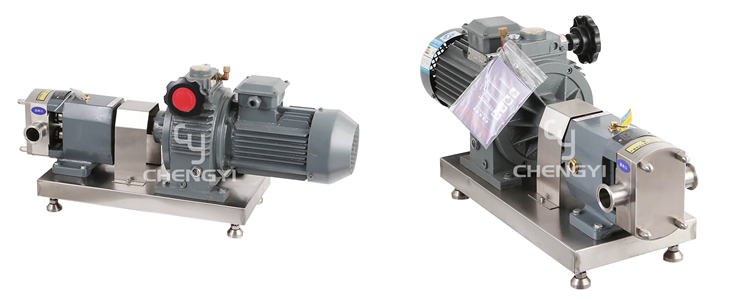

This cam lobe pump is a multi-purpose transfer pump which adopts two-lobe, tri-lobe, butterfly or multi-lobe rotor. As a sanitary volumetric delivery pump, it has the characteristics of low speed, high output torque, high temperature resistance, corrosion resistance, etc. Its unique working principle and characteristics are embodied in conveying high viscosity, high temperature, and highly corrosive materials. Its conveying process is smooth and continuous, and it can ensure that the physical properties of the materials are not broken during the conveying process, and the viscosity of the conveyable materials can be up to 1,000,000 CP.

Ransmission Section Selection

Motor

+ Fixed Ratio Reducer: this method of transmission is simple, the rotor

speed is constant, which also determines the flowrate is not

adjustable.

Motor +

Mechanical Friction Type Stepless Transmission: this type of

transmission is manually adjusted to achieve variable speed.It is

characterized by safe and reliable, large torque, flow adjustable

stepless. Disadvantages are non-automatic adjustment and more

troublesome. The speed must be adjusted in the working process, and it

must not be adjusted under stop state. Please refer to the

manufacturer's instructions for use and maintenance specifications.

Converter Motor + Converter: the speed can be automatically adjusted in this way, which means that the flow can be adjusted steplessly. The advantage is that the degree of automation is high and the low speed torque is large; the disadvantage is that the price of the inverter is relatively high. Please refer to the manufacturer's instruction manual for maintenance specifications.

Converter Motor + Converter: the speed can be automatically adjusted in this way, which means that the flow can be adjusted steplessly. The advantage is that the degree of automation is high and the low speed torque is large; the disadvantage is that the price of the inverter is relatively high. Please refer to the manufacturer's instruction manual for maintenance specifications.

Sanitary Rotor Pump

Note

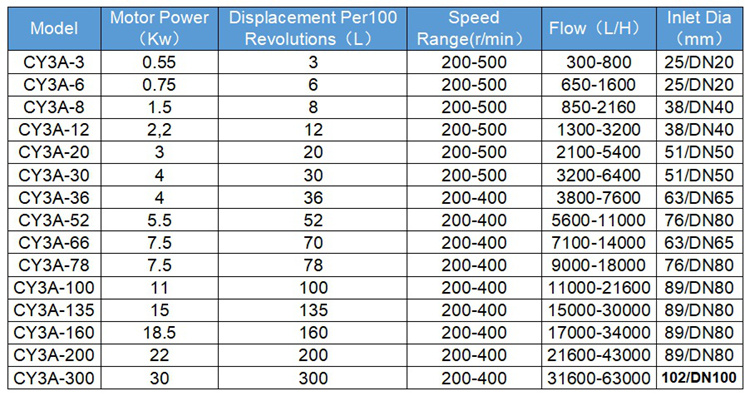

The

flow range in the table refers to the data measured when the medium is

“water”.It adopts stepless variable speed motor or frequency converter

to adjust the speed range from 200 to 900 rpm. When conveying high

viscosity concentrated liquid, the motor power must be increased. The

data in this form is subject to change without prior notice. The correct

parameters are subject to the actual product provided.