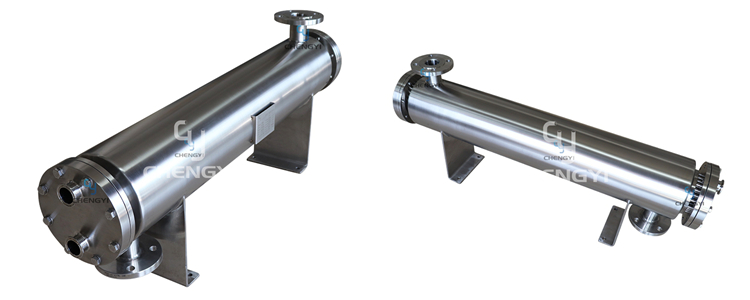

Product description

Sanitary Shell & tube heat exchanger, especially meets the high hygienic demands of pharmaceutical industry. Usually for WFI point of cooling, modular integrate, process cooling or heating ,etc.

Working principle

The material flows inside tube, the cold and hot medium flows inside shell, and the material and the cold and hot medium carry on the high efficiency heat exchange through the compact arrangement tube bundle to meet the technological temperature requirement. Because the heat exchanger adopts the double tube plate /Shell & Tube design, the bidirectional cross-contamination between the material and the cold and hot medium is completely eliminated.

Product performance and characteristics

Contacted material: stainless steel 304,316L

Internal surface finish: Ra<0.5μm

Simple structure, high heat transfer rate, easy to use

Dual-tube design to prevent leakage of service media to products

Meeting cGMP requirements

Standard design and maintenance-free

Customized upon request

Connection mode: tube side: TC Connection, Flange shell side: TC connection or Flange connection

Applications

Heating and cooling of Purified water and WFI water

Heating and cooling of liquid material in process production

Sanitary Shell & tube heat exchanger, especially meets the high hygienic demands of pharmaceutical industry. Usually for WFI point of cooling, modular integrate, process cooling or heating ,etc.

Working principle

The material flows inside tube, the cold and hot medium flows inside shell, and the material and the cold and hot medium carry on the high efficiency heat exchange through the compact arrangement tube bundle to meet the technological temperature requirement. Because the heat exchanger adopts the double tube plate /Shell & Tube design, the bidirectional cross-contamination between the material and the cold and hot medium is completely eliminated.

Product performance and characteristics

Contacted material: stainless steel 304,316L

Internal surface finish: Ra<0.5μm

Simple structure, high heat transfer rate, easy to use

Dual-tube design to prevent leakage of service media to products

Meeting cGMP requirements

Standard design and maintenance-free

Customized upon request

Connection mode: tube side: TC Connection, Flange shell side: TC connection or Flange connection

Applications

Heating and cooling of Purified water and WFI water

Heating and cooling of liquid material in process production

Sanitary Shell & Tube Heat Exchanger

Specification :0.45M2~20M2 ( It is designed according to client's detail requirments)