Application

Reliable modular design enables the user to obtain an optimal valve that meets the requirements of the application. This application is required throughout all types of anti-mixing operations requiring two different products to flow through the same valve. This anti-mixing valve provides a large number of configuration combinations to meet the specific requirements and functions of the system. In the application field of anti-mixing valve, it is outstanding, easy to repair and maintain, widely used in various fields of sanitary industry.

Work principle

Anti-mixing valves are operated remotely by compressed air. The valve is normally closed. This type of valve has two independent spool seals, which in normal working condition will form a leak chamber with atmospheric connection. In the case of occasional accidental product leaks, the product flows into the leak chamber and is discharged from the outlet. The cavity is closed when the valve is open. As a result, the delivered product can flow from one pipeline to another.

The valve can be cleaned by CIP, the user can avoid water hammer multi-stage selection measures. In the valve normal long-distance process, there is no product overflow.

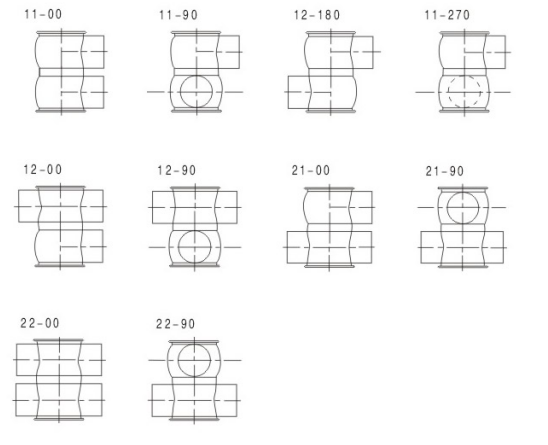

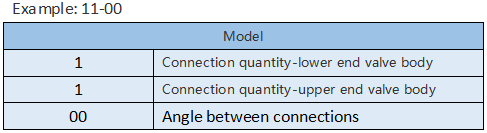

Valve body type

Specifications

Specification:1"-6", DN25-DN150

Working pressure:0~6bar

Working temperature:-10℃~+120℃

Connection:clamp, weld, thread

Connection standard: ISO,DIN,IDF,SMS,3A,etc

Material:304, 316L