Application

This series of valve are major let the medium reach the purpose of reversing or end stop, because the good seal ability and clean ability, they are extensively use to different sanitary industry areas.

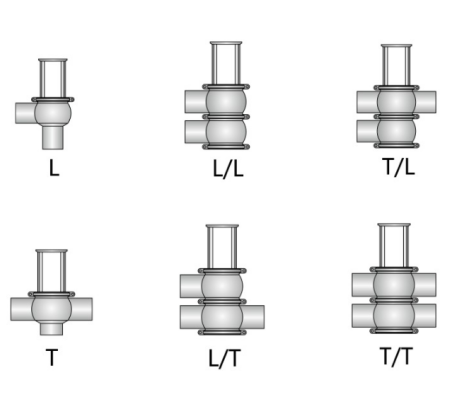

Work principle

The series of pneumatic cut-off / reversing valve change the energy which process by compressed air to the mechanical energy, the mechanical energy can drive the valve rod axial moving, thus move the different location of seal elements, which can control the switch for inlet of pipeline, finally realize the purpose of medium reversing or stop.

The manual cut-off reversing valve series control by handle, also reach the purpose of medium reversing or stop at the end.

Standard design

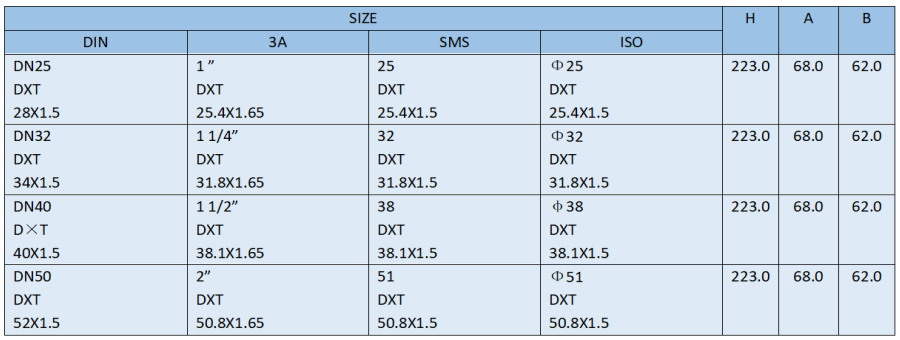

The series of valve have two types valve, that is the cut-off type and reversing type, the cut-off type can made of two or three pipeline connector, the reversing valve can made at three to five pipeline connector, their variety fully satisfied the needed of market.

Material:

Steel parts: stainless steel 304, stainless steel 316L.

Seal: PTFE, O type seal ring

Up diaphragm: NBR diaphragm and standard diaphragm

Down diaphragm: PTFE, EPDM and standard diaphragm

O type ring: NBR diaphragm diaphragm and standard diaphragm.

(Remarks: when the temperature beyond 95 degree, the diaphragm need choose PTFE, O type ring choose EPDM.)

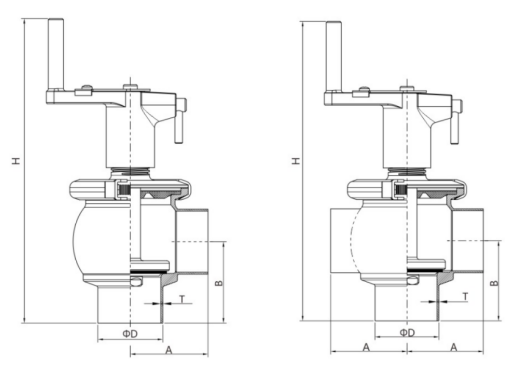

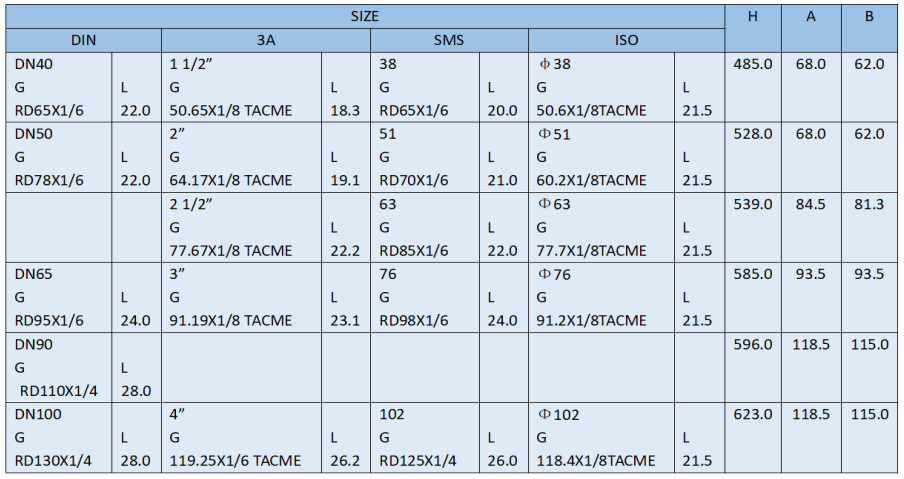

Specification

Specification:1"-4", DN25-DN100

Working pressure:0~6bar

Working temperature:-10℃~+120℃

Connection:clamp, weld, thread

Connection standard: ISO,DIN,IDF,SMS,3A,etc

Nozzle direction

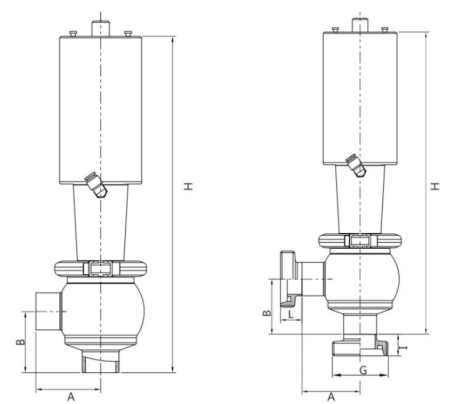

Pneumatic stop valve

Manual stop valve