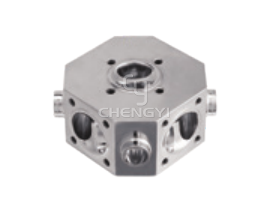

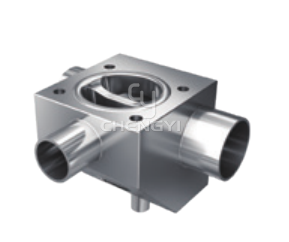

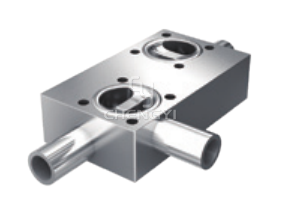

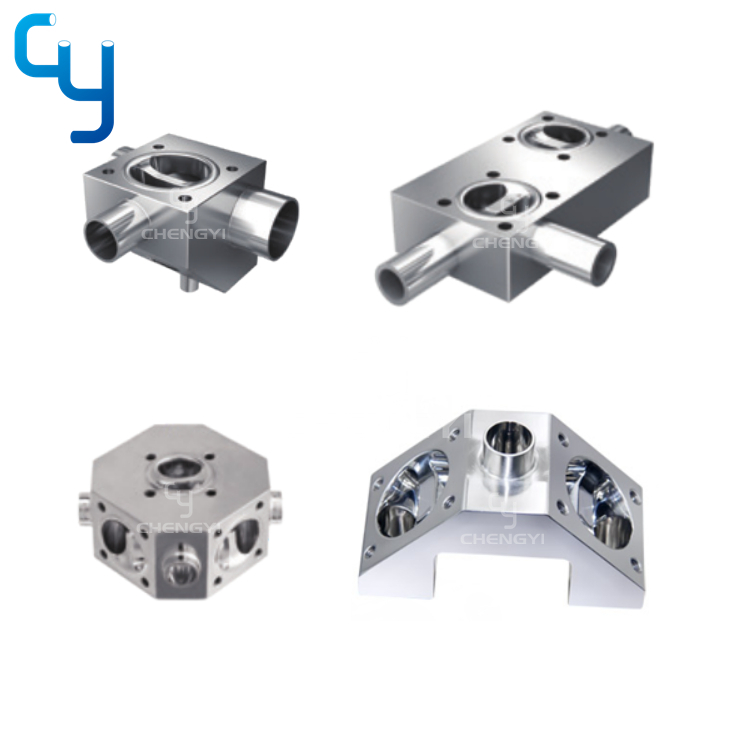

According to customers' requirements, after learning about the customer on-site technical requirements, installation location and the flowing direction relationship among the various flowing channels, a piece of forged stainless steel is made into a multi-channel combined valve through CNC machining center to implement online CIP and SIP functions. Because of the design of this valve is unique, the residual between valve seats should be as little as possible, it requires the valve designer has a good understanding of the process and rich experience. Our company have professional design teams and software, which is able to quickly complete the 3D design, timely communicate with customers and confirm drawings.

It can be customized due to needs of customers for diaphragm valves needed by all kinds of working conditions. This kind of products is made by the machining center for forging the integral materials, better cleanness can be obtained from this, and it also has the excellent welding property and mechanical property.

Application

Diaphragm valve is a series of sanitary diaphragm valve, it is widely used in wine, dairy products, beverage, food and pharmaceutical industries. Achieving the requirement of control and open/close for the pipeline system.

Work principle

The diaphragm valve is normally closed, where the diaphragm clings to the inner cavity of the valve body and closes the pipeline flow path. When the diaphragm valve needs to be cleaned or opened, the stem moves upward by rotating the handwheel manually or driving the pneumatic control actuator, and the spherical diaphragm bends upward, so that the valve is open and reach the requirement of clean and open. The diaphragm separates the inner cavity of the lower valve body from the inner cavity of the upper valve cover, so that the stem and valve core located in the upper part of the diaphragm are not corroded by the medium, thus the packing sealing structure is eliminated and the medium leakage will not occur. Optimized valve body design made the cleaning liquid discharge fully, do not form a retention phenomenon.

Material

Steel parts: 304 stainless steel, 316L stainless steel

Seals: EPDM+PTFE which are made of imported sealing materials. Using the special technology of CHENGYI, a connecting bolt is combined with EPDM/PTFE to form a whole sealing part. The sealing part and contact part of the PTFE material have good cold resistance(-25℃),with long working temperature reaching +130℃ and sterilization temperature 150℃≤30min, which has good tolerance to various chemical agents and excellent wear resistance to fluids.

Standard design

Standard: DIN, 3A, SMS, ISO/ IDF, BS/RJT, ASME/BPE etc.

The parts of valves: an actuator, diaphragm and body which assemble together with bolts and nuts. The entire valve assembly in meticulously. The actuator is manual, the diaphragm made of artificial rubber which can have all kinds of soft and hard degree.

Technical Data

Material | Contact with the product parts | 316L(1.4404) |

Non contact product parts | 304(1.4301) | |

Sealing material | Standard | EPDM+PTFE |

Option | EPDM | |

Pressure | Working pressure | Manual 0~10bar、pneumatic 0~4.5bar |

Temperature | Working temperature | EPDM+PTFE-20~+130℃ / EPDM-20~+120℃ |

Sterilization temperature | 150℃≤30min | |

Surface treatment | Internal surface finish | Ra0.4~0.6μm |

External surface finish | Ra0.8~1.6μm | |

Connection | Connection:clamp, weld, thread | |

Standards | 3A, DIN, SMS, IDF, RJT, ISO | |

Specification | 1/2"-4 ", DN10-DN100 | |